Introduction

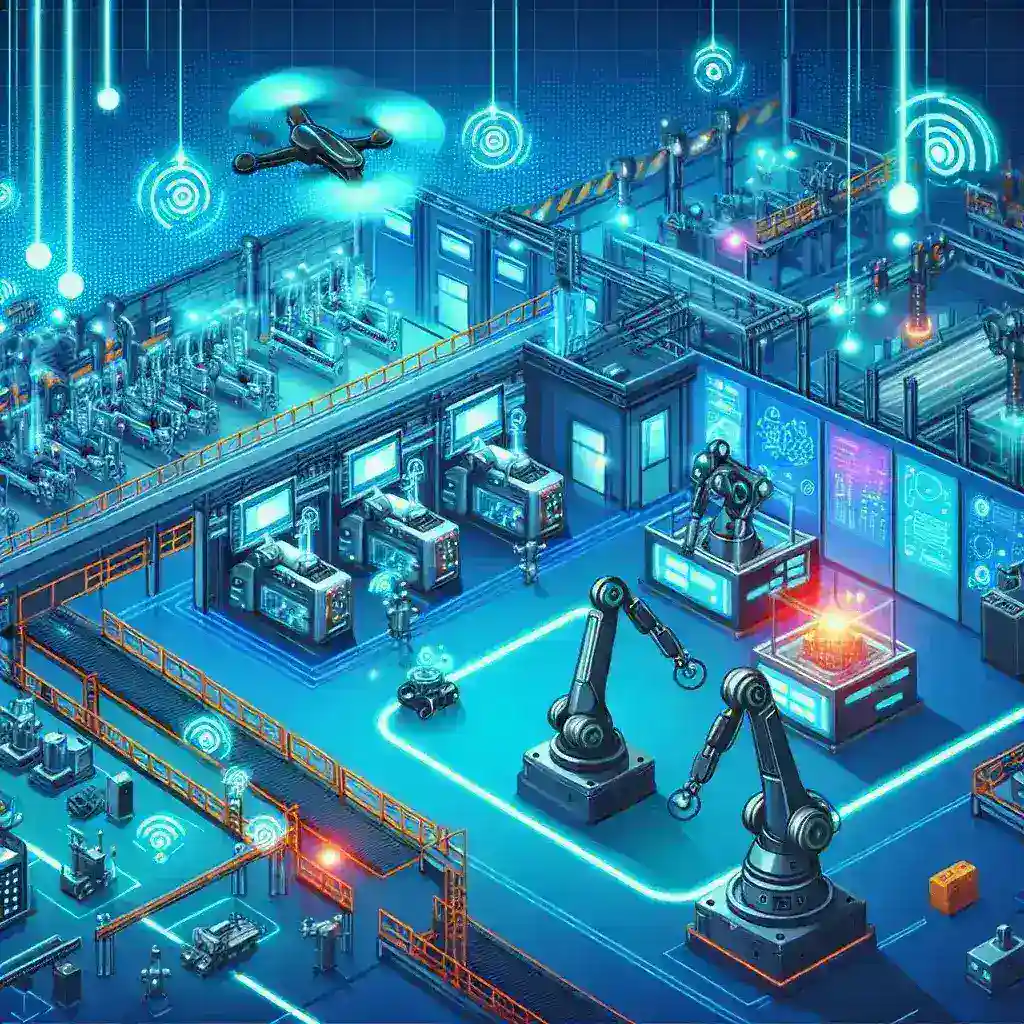

In the rapidly evolving landscape of manufacturing, companies are continuously seeking innovative solutions to enhance operational efficiency and productivity. Among the leaders in this technological transformation is IBM, which has recently unveiled its cutting-edge IBM Watson industrial AI solutions. These solutions aim to address key challenges in the manufacturing sector, leveraging advanced analytics and artificial intelligence to optimize processes and drive better decision-making.

The Role of AI in Manufacturing

Artificial Intelligence (AI) is revolutionizing the manufacturing industry by introducing intelligent automation and data-driven insights. By integrating AI technologies, manufacturers can:

- Increase Operational Efficiency: AI algorithms analyze vast amounts of data to identify inefficiencies and streamline production processes.

- Enhance Quality Control: AI systems can detect defects and anomalies in real-time, ensuring higher quality standards.

- Predictive Maintenance: AI solutions enable manufacturers to predict equipment failures before they occur, reducing downtime and maintenance costs.

- Optimize Supply Chain Management: AI helps in analyzing market trends and consumer demand, leading to better inventory management.

IBM Watson: A Leader in AI Innovation

IBM Watson has positioned itself as a pioneer in applying AI to various industries, including manufacturing. With its robust capabilities, Watson empowers organizations to harness the power of data. The introduction of industrial AI solutions marks a significant milestone in IBM’s journey to transform manufacturing practices.

Key Features of IBM Watson’s Industrial AI Solutions

The new industrial AI solutions from IBM Watson come equipped with several features designed to enhance manufacturing processes:

- Advanced Analytics: Watson’s analytical capabilities allow manufacturers to sift through complex datasets, extracting actionable insights that drive operational improvements.

- Machine Learning: With machine learning, Watson continually improves its algorithms based on new data, ensuring that processes evolve over time.

- Natural Language Processing: Watson’s ability to understand and process human language enables seamless communication between machines and operators.

- Integration with IoT: IBM Watson’s solutions can easily integrate with Internet of Things (IoT) devices, providing real-time data for enhanced decision-making.

Real-world Applications

Many manufacturers are already leveraging IBM Watson’s industrial AI solutions to gain a competitive edge. Here are some notable applications:

Case Study: Automotive Manufacturing

A leading automotive manufacturer implemented IBM Watson’s AI solutions to optimize its assembly line operations. By utilizing advanced analytics, the company was able to:

- Identify bottlenecks in the production process, which led to a 20% increase in throughput.

- Reduce defects by 30% through enhanced quality control measures.

- Implement predictive maintenance, resulting in a 15% reduction in maintenance costs.

Case Study: Electronics Production

Another example is an electronics manufacturer that adopted Watson’s AI capabilities to enhance its supply chain management. The results included:

- Improved demand forecasting accuracy by 25%, allowing for more efficient inventory management.

- Reduction in lead times through optimized logistics planning.

- Increased customer satisfaction due to timely deliveries and reduced stockouts.

Future Predictions for AI in Manufacturing

As IBM Watson continues to innovate, the future of AI in manufacturing looks promising. Experts predict that:

- AI will become increasingly integrated into all facets of manufacturing, from design to production to distribution.

- Predictive analytics will evolve, with AI systems capable of not only predicting failures but also suggesting proactive measures.

- Collaboration between AI and human workers will lead to enhanced creativity and innovation in product development.

Challenges and Considerations

Despite the advantages of implementing AI solutions, manufacturers must also consider several challenges:

- Data Privacy and Security: As AI systems rely on large datasets, ensuring data privacy and cybersecurity is paramount.

- Workforce Adaptation: Employees may require training to adapt to new technologies, which can be time-consuming and costly.

- Investment Costs: The initial investment in AI technology can be significant, and companies must weigh the potential ROI.

Conclusion

IBM Watson’s introduction of industrial AI solutions signifies a new era for manufacturing optimization. By embracing these innovative technologies, manufacturers can enhance efficiency, reduce costs, and improve product quality. As the industry continues to evolve, the integration of AI will undoubtedly play a crucial role in shaping the future of manufacturing, driving it toward greater innovation and sustainability.

Call to Action

For manufacturers looking to stay ahead in this competitive landscape, now is the time to explore IBM Watson’s industrial AI solutions. Embrace the future of manufacturing by leveraging AI to optimize your processes and achieve unprecedented levels of efficiency and quality.